|

|

of Florida Inc. |

|

|

Specifications

Spectra Shields Tri-metal process consists of three Layers of metal on an engineering resin base.

The first layer, Electroless copper, is applied using a proprietary patented process which bonds to the molecular structure of the resin. A Solid Copper layer is then Electro-plated over the Electroless layer to form a Solid RF Barrier. A Solid Nickel layer is then electroplated over the copper layer to form a tough, durable, protective finish. This process is applied to all surfaces, inside and out, creating six layers of shielding from a cross sectional view.

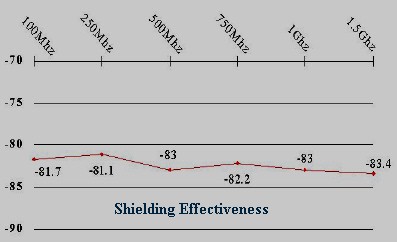

Spectra Shield meets or exceeds the following test as performed by

independent testing facility on a standard 1-1/2 X 3-1/2" shield.

Salt Fog per MIL-STD-810E Method 509.3 Test Conditions = 5% salt solution, temperature = 95 degrees F. Salt Fog fallout rate of .5 to 3.0 ml/80cm 2/hr. Total exposure for 48 hours.

Thermal Test consist of parts thermal cycled from -40 to +70 degree C for eight complete cycles @ three hours per cycle, with a one hour dwell at extreme temperatures.

High Temperature resins are available to 700 degree F.

Please feel free to contact SAI to discuss your specific applications and needs. Our engineers are available to assist in developing a solution for all your shielding requirements.